|

Check

Valves (Non Return Valve)

-

Swing

Check Valve

-

Duel

Plate Check Valve

-

Wafer

Type Check Valve (Plate Type)

-

Disc

Check Valve

-

Flap

Type Check Valve

-

Forged

Steel Lift Check Valve

-

Cast

Steel Lift Check Valve

Swing

Check

Valves

Flosteer Swing check valves are ideally suitable for vertical and horizontal application. A range of Check Valves (Non-Return Valves) suitable for oil, gas, water, refining, power and chemical applications where the prevention of flow reversal is mandatory. Flosteer Check Valves are Bolted cover design up to 600# and above pressure seal design.

Stellited trims are provided for all above 600# as a manufacturing standard of “FLOSTEER” valves and in lower rating also on request.

FLOSTEER Swing Check valves are available under any Third party inspection including IBR (Indian Boiler Regulation). Swing Check valves can be supplied with Titling disc design, Counter weight or Dash pot arrangement.

Swing Check Valve

| Stnadards: |

|

| Design

Standard |

BS 1868/API 6D |

| Inspection

& Testing Standard |

BS 6755/API 6D |

| Face To Face |

As Per ANSI B

16.10 |

| End Connection |

Flanged End To

ANSI B 16.5/BS 10 Table

Buttweld End

To ANSI B 16.25 |

| Size Range |

1" To

24" |

| Pressure

Rating |

150# To 1500# |

| Material Specification: |

| Body

/ Cover / Hinge |

ASTM A 216 GR.

WCB

ASTM A 217 GR.

WC1/WC6/WC9/WC11

ASTM A 352 GR.

LCB/LC3

ASTM A 351 GR.

CF 8 /CF 8M/CF 3/CF 3M/CN 7M

IS 210 GR. FG

200/220/250/260

|

| Disc |

AISI 410 (13%

Cr.) /AISI 304/316/304L/316L/Alloy 20 |

| Seat |

AISI 410 (13%

Cr.) /AISI 304/316/304L/316L/Alloy 20 |

| Hinge Pin |

AISI 410 (13%

Cr.) /AISI 304/316/304L/316L/Alloy 20 |

| Gasket |

CAF/Grafoil/S.S.

Spiral Wound With CAF/Grafoil/P.T.F.E. |

| Disc Lock Nut |

A 194 GR.

2H/S.S. 304/316 |

| Stud & Nut |

ASTM A 193 GR.

B7/ A 194 GR. 2H/S.S. 304/316 |

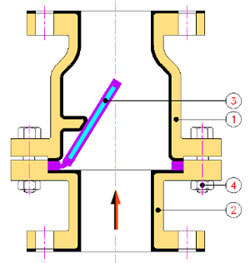

Dual

Plate Check Valve (NRV)

Flosteer Dual Plate, Wafer Check Valve has One Piece cast heavy stronger Body configuration provides reduced weight and size compare to a swing check valve or lift check valve. This results savings in Initial cost, space and pipe support element installation.

The Dual Plate, Wafer Check Valve employs two-spring-loaded plates hinged on a central hinge pin. When the flow decreases, the plates close by the action of torsion spring before flow reversal takes place. All features put together make the Dual Plate Check Valve as the most efficient & versatile design. It is also referred to as SILENT CHECK VALVE

It is much easier to install between standard gaskets and line flanges, and therefore is more cost effective to install and to maintain.

Its design complies with API 594 and API 6D, testing with API 598.

Features:

-

Light Weight, Versatile Design, and 80 to 90% lighter then conventional full body check valve.

-

Reduces pipe supports, simplifies piping, easier, less costly installation.

-

Spring Loaded double door design has low cracking pressure.

-

Disc open 80% to ensure positive closing

-

Materials and trims available for all services within temperature range.

-

Rubber To Metal or Metal To Metal Seat available

-

Neoprene, Buna-N, EPDM, Viton®, Silicon etc.

| Standard: |

| Design Standard |

API 6D / API 594 |

| Testing Standard |

API 598 |

| Pressure Class |

150# to 300# |

| End Connection |

Wafer Type, Flangeless

Suitable To Mount Between

ANSI B 16.5/BS 10 Table/DIN/JIS/IS Flange |

| Nomeclature: |

| Body |

IS 210 GR. FG 200/220

ASTM A 216 GR. WCB

ASTM A 217 GR. WC 1 / WC 6 /WC 9 / WC 11

ASTM A 352 GR. LCB / LC 3

ASTM A 351 GR. CF 8 / CF 8M / CF 3/CF 3M |

| Disc |

ASTM A 216 GR. WCB

ASTM A 217 GR. WC 1 / WC 6 /WC 9 / WC 11

ASTM A 352 GR. LCB / LC 3

ASTM A 351 GR. CF 8 / CF 8M / CF 3/CF 3M |

| Hinge/Stop Pin |

AISI 410 / 304 / 316 / 304L / 316L |

| Seat (Moulded) |

Neoprene / Nitrile / Buna-N/ NBR / EPDM /Silicon / Viton

Spring : S.S. 304 / 316 / 304L / 316 L

Lifting Hook : C.S. / S.S 304 / 316 |

Wafer

Type Check Valve (Plate Type)

Flosteer Wafer Type Check Valve has short face-to-face dimensions and low weight allows a simple space saving installation between the companion flanges. The valves are suitable to mounting between weld neck or slip on type companion flanges of different standards.

They are specially developed for applications where a low-pressure loss is essential. Opening and closing of the valve will take place at an extremely low-pressure difference over the valve disc. The eccentric disc shaft combination with the disc seat guarantees a positive shut off returning media. Wafer check valves are becoming the preferred type of check valve for most applications, due to their compact design and relatively low cost.

Wafer Type Check Valve (Plate Type)

Features:

- Body Type: Single Plate, Short Type

- Suitable For Horizontal and Vertical Mounting

- Shorter overall length, mounting requires minimum space.

- Low Pressure Drop

- Easy to Install

- Less Weight

- Maintenance Free

- End Connection: Wafer Type, Flangeless

- Size Range: 1” To 42”

- Pressure Rating: 150#

- Seat Leakage: Zero Leakage, Tight Shut Off

- Temperature Range: -250 To + 2000 C

- Mounting Between: ANSI B 16.5 / BS 10 /DIN /IS/JIS Flanges

- Design Standard: API 6D

- Testing: API 598

- Face To Face: ANSI B 16.10

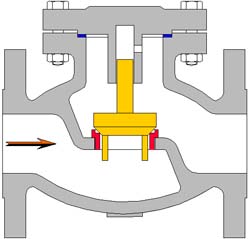

Disc

Check Valve

Flosteer Disc Check Valves feature a wafer type, compact and rugged cast steel design and are suitable for any process liquid, air, gas, steam etc. Disc check valves are opened by the pressure of fluid and closed through compression spring as soon as flow stops thus preventing reverse flow.

Advantage of these check valve is they can be mount between pipe flanges in any direction. Body Seat available in Metal-to-Metal and Soft seat also.

|

Disc Check Valve

|

|

FEATURES:

Compact & Rugged Design

Less Weight

Easy To Installation

Maintenance Free

Zero Leakage (In Soft Seat)

| Standard: |

| Design

Standard |

DIN EN 558-2 |

| Testing

Standard |

DIN 3230 / API 598 |

| End

Connection |

Wafer Type, Flangeless

Suitable To Mount Between

ANSI B 16.5/BS 10 Table/DIN/JIS/IS Flange |

| Rating |

150# to 300# |

| Size Range |

15MM to 100MM |

| Nomenclature: |

| Body |

ASTM A 216 GR. WCB

ASTM A 351 GR. CF 8 /CF 8M / CF 3 / CF 3M

Star Guide : ASTM A 216 GR. WCB

ASTM A 351 GR. CF 8 /CF 8M / CF 3 / CF 3M |

| Seat |

Metal To Metal – Integral Body –S.S. 304/316/304L/316L

Soft Seat – P.T.F.E./Neoprene/EPDM/Nitrile/Buna-N/Silicon/Viton |

| Disc |

ASTM A 351 GR. CF 8 /CF 8M / CF 3 / CF 3M

Spring : S.S. 304 / 316 / 304L / 316L

Circlip : S.S. 304 / 316 / 304L / 316L |

Flap

Type Check Valve

Rubber Lined & Unlined

Flosteer Flap Type Check Valves are available in Two Piece Body Construction with Rubber Lining or Without Lining. Flosteer Designed Flap Type Check Valves gives Zero Leakage due to Rubber Moulded Flap Disc.

| Standard: |

| Design & Testing Std. |

Mfg. Standard |

| Pressure Rating |

PN 7 |

| End Connection |

Flanged End |

| Drilling |

As Per ANSI B 16.5/BS 10 Table/DIN/JIS/IS Std. |

| Leakage Class |

Class VI (Zero Leakage) |

| Nomenclature: |

| Body / End Piece |

IS 210 GR. FG 200 / 200

S.G. Iron / Ductile Iron

ASTM A 216 GR. WCB |

| Flap Disc |

C.S./S.S. With Neoprene/EPDM/Nitrile/NBR/Silicon/Viton Rubber Lined |

| Fasteners |

C.S. / ASTM A 193 GR. B7/ A 194 GR. 2H / S.S. 304 / 316 |

| Rubber Lining |

Neoprene/EPDM/Ebonite/Hypalon/Silicon/Viton

Lining Thickness – 3.0mm Minimum

Lining Test (Spark Test) – 15 KV DC |

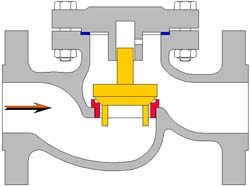

Forged

Steel Lift Check Valve

Forged Steel Check Valve

Cast Steel Lift Check Valve

|

|

| ND Lift Check Valve

|

ASA Lift Check Valve

|

Flosteer Lift Type Check Valves are designed to reduce the flow resistance and pressure drop to the minimum possible extend. Lift check valves are suitable to mount in horizontal position only. Accurately machined, lapped and screwed in seat ring ensures tight shut of and long life. The valve disc is perfectly designed, accurately machined and guided for efficient automatic shut off at zero pressure. As an option seat can b weld deposited or integrated with body in case of stainless steel and other high alloy metals.

Flosteer Lift Check Valves are available from size range 1” t 12” in Flanged End / Butt Weld End Connection, generally in all material of construction and up to 600# pressure rating.

|